December 1, 2021

Torsten’s Training Tip: Making the Right Material Choices

Bad choices may make good stories – but not good parts

If polymers fail in their practical use, you often hear the comment the part failed because it’s made from ‘plastic.’ However, the choice of a plastic or a polymer and how it is processed has a substantial impact on the outcome of a molded part and its suitability for the application it is designed for.

Processing methods and temperature behavior categorize polymers. The major groups are thermoplastics, thermosets, and elastomers. There are also compounds made up of polymer blends, co-polymers, composites, and thermoplastic elastomers.

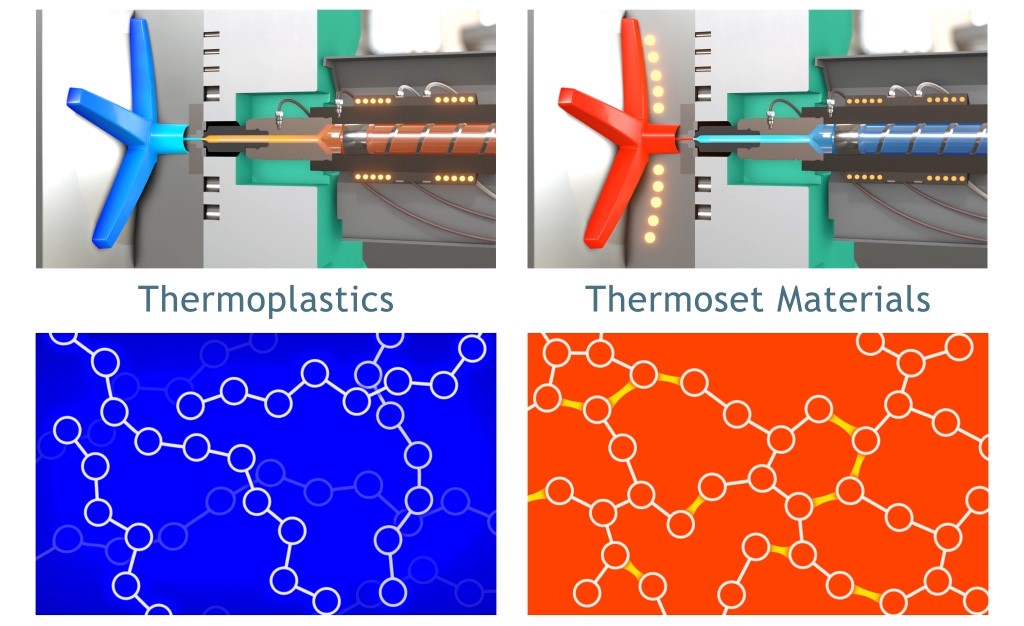

The most common group of polymers are thermoplastics. These are polymers that melt by heating and solidify by cooling. This behavior is different from Thermoset materials.

Thermoset materials, generally rigid polymers, are injected at a low temperature and then cured with heat inside the mold. This creates an internal chemical reaction that forces the molecular chains to cross-link and form a solid molecular structure. The molecular chains generate a chemical bond that cannot be re-melted. Find more details on this video.

Thermoplastic Categories

Within the category of thermoplastics, there are thousands of different base materials and grades. Although it’s virtually impossible to understand every available material fully, understanding essential polymer characteristics is imperative to successful part and mold design. This group is further broken down into two main categories, amorphous and semi-crystalline.

As materials flow, their molecular chains align. When they stop flowing, the molecular chains return to their natural coil-type structures. When polymers return to their natural, relaxed molecular state, the molded part shows very little molded-in stress and, therefore, less potential part warpage and higher dimensional stability.

Main Polymer Categories

1) Amorphous materials have a comprehensive process range and can be molded with fewer challenges resulting in molded parts that are more dimensionally stable.

2) Semi-crystalline materials have a narrower material processing temperature range. These materials are opaque, have good resistance to chemicals, and lower moisture absorption. However, they have higher shrinkages. This is important for process technicians to understand when molding semi-crystalline materials.

A general understanding of polymers’ essential properties and structures will help part and mold designers and processors to make choices and decisions that will optimize the final part.

For more information on polymers and training:

Full demo lesson on polymers materials <www.krusetraining.com>