May 4, 2022

Torsten’s Training Tip: Sink Marks and Voids

Good design processes, virtual CAE simulations, and proper training tools can be used to address molding defects before finalizing part and mold designs.

Two common and related injection molding defects, sink marks and voids, result from excessive polymer material shrinkage. Because it is essential to produce high-quality parts free of molding defects, understanding the causes to reduce or eliminate sink marks in molded parts can be very helpful. Let’s review some basics.

Sink Marks

A sink mark is a surface depression that generally occurs in thicker wall sections of molded parts. Sinks can also appear above ribs, bosses, and other part design features. A void is an internal bubble inside the part and can be visible in opaque and clear uncolored materials.

Sinks develop during the cooling phase both inside and outside the mold when the frozen skin section of a molded part is not solid or stiff enough and is drawn inward. This is a post-molding shrinkage behavior due to strong thermal contraction forces.

Voids

Voids form when the frozen skin section is so stiff and strong that thermal contraction forces cause micro-porosity, causing the material to pull itself apart literally. This action creates a vacuum void.

Various aspects of molding can cause sink marks and voids. Machine-related issues, polymer material factors, part and mold design-related challenges, and process set-up issues can all affect sink marks and void formation.

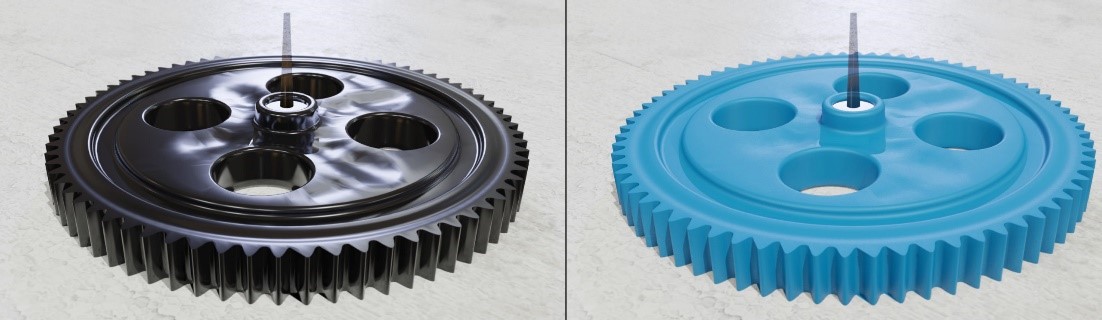

Sink marks forming on a simple gear part

Here is an example of sink marks displayed on three versions of the same part:

All new part designs should be evaluated to reduce or eliminate the risk of sinks and voids. Uniform wall thickness, proper gate location, and an optimized process are critical in minimizing the likelihood of sinks and voids.

Kruse Training Molding Defects: Sink Marks and Voids, Part 1

The full Kruse Training Molding Defects: Sink Marks and Voids, Part 1 is available by subscription.

Please contact John Ward for more information @ john@turnergroup.net