May 31, 2022

Stents Save Lives!

These small flexible tubes are used to reopen blocked or narrowed blood vessels, most commonly during heart attacks, to repair aneurysms or address urinary tract obstructions. The increasingly sophisticated uses of medical plastic tubing demand that processors exercise ever-greater control over key process factors, including quality, precision, repeatability, traceability, and cleanliness.

These increasingly complex tubing configurations include micro-bore tubing sizes (less than 0.060” in diameter) for heart and brain catheters; multi-lumen structures for diagnostic, interventional, and therapeutic uses; complex bump profiles for neonatal and neurovascular; and while meeting tight tolerances for tube structure and material properties.

Accuracy and quality demands are greater than ever

The need for accuracy and quality is greater today than ever before. Years of development efforts by extrusion equipment makers have resulted in a steady stream of improvements that make the production of medical plastic catheters and stents more repeatable, controllable, and automated than ever before while reducing the need for off-line, manual quality assurance, cutting, and finishing work.

From the beginning to the end and back again

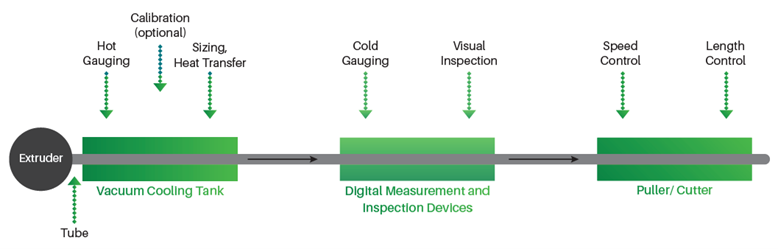

Starting with the extruder, medical tube production typically follows a six- or seven-step process that encompasses several different types of equipment, including the vacuum cooling tank, several gauging and measurement devices, a puller and a cutter.

Beginning at the beginning

The extruder. We all know that the extruder is key to the preparation of the melt. Controls, however, are critical to bringing all the processes together. Optimum screw design, modular barrels and unique wire management are part of the process.

Beginning at the end

The puller. Because precise regulation of the speed of the medical tube extrusion process is crucial to a quality product, let’s begin by considering the puller, or in many cases, the puller/cutter, which is typically the last piece of downstream extrusion process equipment. These features enable them to pull extruded tubes through the process at extremely precise rates or to adjust speeds in tiny increments.

Back to the beginning

With speed and length control out of the way, we return to the beginning of the extrusion process, where the tube leaves the extruder and passes through air on its way to the vacuum/cooling tank.

The Vacuum Cooling/Sizing Tank. Controlling the sizing of small-diameter, single- or multi-lumen medical tubing has required equipment makers like Conair to scale down previous vacuum sizing/cooling equipment, reduce water turbulence, and provide finer, more precise quantification and control of vacuum level, water temperature, and water flow. Within these tanks, extruded tubes typically undergo several different operations:

- Hot gauging. The first of several sensors in downstream extrusion controls is an ultrasonic gauge. Positioned underwater in the first 12 to 18 inches of the vacuum cooling/sizing tank, this gauge measures tube OD and wall thickness before the tube has had a chance to cool. Reading wall thickness at four points around the tube’s circumference, the gauge measures the uniformity of the tubing wall and allows for on-the-fly control of this important variable. This is a substantial improvement over other control techniques that provide no feedback until further downstream in the process.

- Sizing. Drawing a vacuum within these cooling/sizing tanks serves multiple purposes. By drawing a vacuum to reduce the pressure of the air and water within the tank, the tank creates a pressure differential that allows air within the extruded tubing to expand outward, which is essential for sizing. Sizing may be aided by a calibration tool, or not, depending on the application. No matter how the tube is sized, drawing vacuum in the cooling tank also can be a significant aid to the cooling process.

How good is great?

Downstream OD measurement and visual inspection. Downstream from the cooling tank, the now-cooled tubing passes through two more inspection steps:

- Cold Gauging. First is a laser gauge, which measures the tubing’s final OD and wall thickness/ovality. If your process is working properly, this “cold gauging” step should be relatively simple, confirming that upstream process controls respond as expected to control tube quality.

- Visual inspection. An automated vision system that can inspect finished tubing for non-programmed variations or flaws in the tubing, such as gels and surface imperfections. Flawed sections are digitally “marked” so that the cutter can cut out and remove them.

Cutter Innovations. Depending on the extruded material and cut-quality standards, several highly precise cutter designs can be used on catheters and stents. For example, Conair’s MedLine puller/cutter can maintain cut-to-length tolerances of ±0.015 inch or better on even small microbore tubing (down to 0.008 inches) when used with specialized input devices.

Who’s in control?

Combining the inputs of in-line gauges and vision systems with servo pullers and software-based control systems makes new levels of extrusion automation possible. Producers can create specialized programs (or “recipes”) for repeatable, automated production of value-added tubing features.

None of these equipment, control, or process innovations can help unless designed for use in a medical production environment like a cleanroom or white room. That’s why equipment makers have developed and marketed cleanroom-ready products for medical extrusion, including US Extruders and Conair, whose products are marketed under the MedLine™ brand and US Extruders MED-EX lines.

MPP West on June 7th

We are bringing all the technology together at the upcoming MPP West event on June 7th in Irvine, CA

A gathering of global experts in the medical device manufacturing industry.

MPP WEST

MEDICAL PROCESSING PANEL

June 7, 2023

ARBURG Technology Center, Irvine, CA