December 15, 2021

Need Quick Mold Change?

Have you ever taken the time to evaluate your mold changeover efficiencies? More than likely there is an opportunity to improve your downtime and increase your output capacity.

Most injection molders can simply decrease their mold change over time just by improving their readiness and preparation. However, to compete in today’s demanding market, manufacturers are having to further increase their efficiencies and reduce inventory costs which require smaller production runs and more effective changeovers.

With quick mold change (QMC) systems you can complete fast and effective lot changes and maximize machine production capacity.

Quick mold changes require training, preparation and the right tools and methodology to achieve the shortest time possible for production changeovers.

With Quick Mold Change (QMC) systems the following benefits can be achieved:

- Increased Production Capacity

- Shorter Lead Times

- Reduced Inventory

- Reduced Labor

- Higher Level of Safety

How Much Time Can You Save?

To estimate the time-saving benefits of what a QMC system can do for you, you should review and complete a time study of your current procedures.

Repeat the study several times as the shift conditions and operators’ performance may vary.

- Identify each step in the process and determine if it can be reduced, carried out simultaneously or even eliminated

- Identify what tools and equipment are required to affect the changeover

- Identify what material handling and preparation is required

Once the mold change procedure has been reviewed, you can then determine how the process can be improved by preparation and readiness. To maximize the full potential of time improvements, you can then identify the QMC tools that will further enhance the procedure and other SMED initiatives.

QMC Solutions

We can help you produce just-in-time with higher speed and more flexibility.

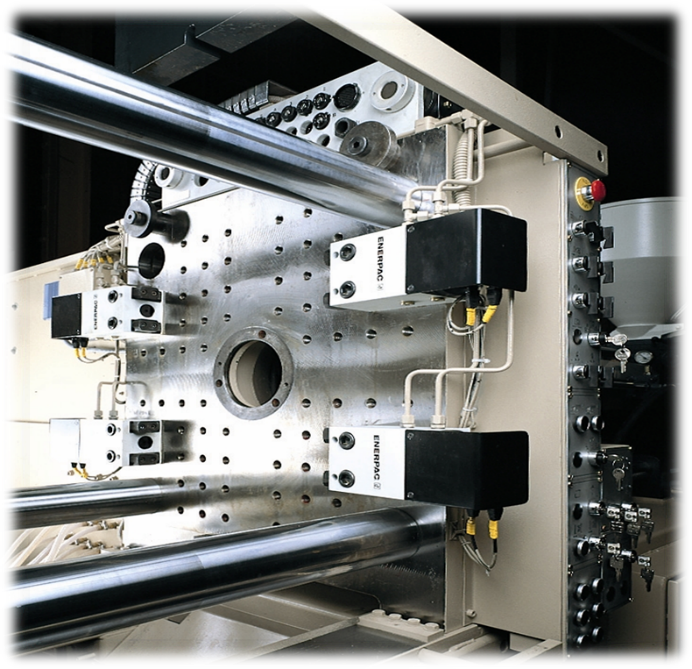

Thanks to EAS change systems, the clamping and release of molds and dies are done in minutes instead of hours.

EAS offers quick clamping and quick-changing systems for plastic injection molding machines and metal stamping presses, as well as multi-coupler solutions.

The company also offers consulting and engineering expertise to ensure maximum machine productivity.

Designed and built for integration into existing as well as new equipment, our solutions include:

- Adaptive clamping systems

- Ejector couplers

- Mono & multi coupler systems

- Mold storage

- Mold change tables & transportation vehicles

- Inspection & mold tilting units

- Pre-rollers

- Project management

- Application engineering

- System installation

- Service and maintenance

- ROI calculations

One of the biggest challenges to adopting quick mold clamping systems is standardization. Most molders are operating with various sized molds that are difficult and costly to adapt.

Magnetic platens are often the solution in many cases as they do not require the same level of standardization.

For instance, you can find more details on Aurburg’s EAS mold change process with pre-rollers.

Whatever your challenges, we can assist you with QMC and SMED audits and inevitably find the best solutions for improving your production efficiencies.