Innovating Cooling Diagnostics: Introducing the Smartflow® Mold Validation Cart

In injection molding, cooling efficiency is one of the most underestimated drivers of cycle time, part quality, and mold longevity. Yet validating water circuits, especially across a large molding operation – often depends on limited maintenance benches, manual testing methods, or time borrowed from production machines.

Smartflow has changed that.

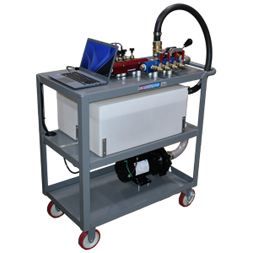

The new Smartflow® Mold Validation Cart brings mobility, precision, and digital documentation together in a single portable platform, enabling mold shops, tooling departments, and processors to verify cooling performance anywhere on the production floor.

The Mold Validation Cart is a portable cooling water line test unit designed specifically for bench testing injection molds. With an integrated pump, reservoir, flow measurement system, data logging tools, and Smartflow’s proven manifold technology, the cart allows users to simulate real process water conditions -without tying up an injection molding machine.

Key system features include:

– On-board 18-gallon water tank and ½ HP pump for consistent cooling water supply

– 4-port supply and return manifold system with ball valves and quick disconnects

– Digital flow monitoring via Smartlink® Tracer®VM Interface with .csv data capture

– SWAP® Valve for fast evacuation of cooling circuits between mold tests

– Powder‑coated mobile cart with locking casters

Mold Maintenance Teams:

Document flow rates before and after cleaning or repair, ensuring molds leave the bench fully optimized.

Mold Builders:

Validate cooling channel performance before shipping new tools. Confirm target flow rates and provide documentation to customers.

Injection Molding Processors:

Troubleshoot restricted, clogged, or leaking water lines outside the press – freeing valuable machine time.

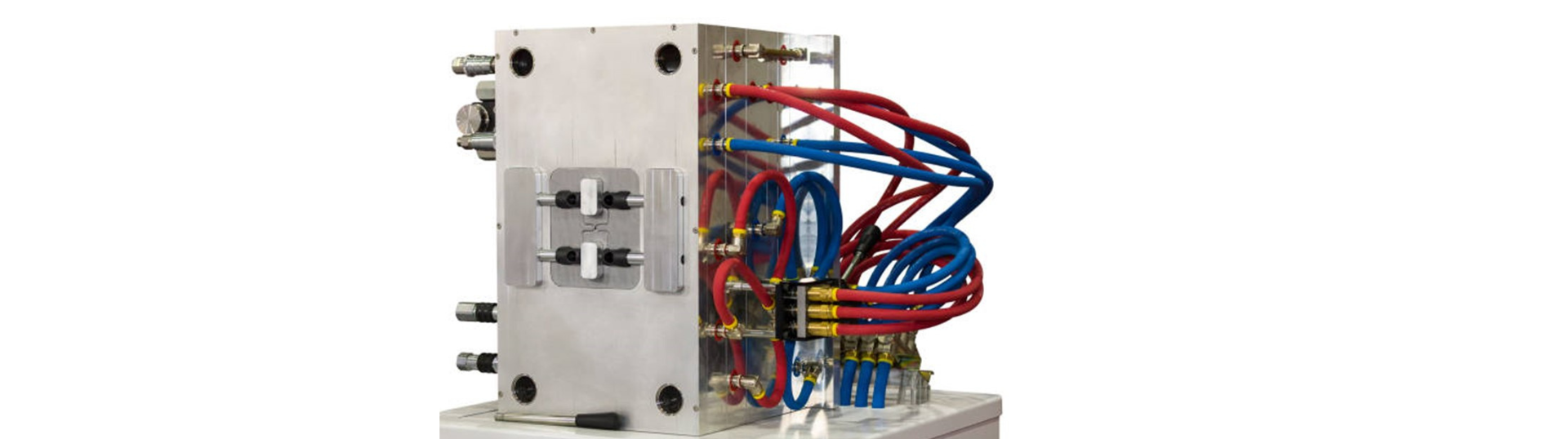

Precision Manifolds:

– 1″ NPT supply manifold with (4) ½” NPT ports and 100‑psi gauge

– 1″ NPT return manifold featuring Tracer®VM Flow Meters, Delta‑Q® Flow Regulators, and 100‑psi gauges

Circuit Isolation & Purging:

Ball valves and quick disconnects allow port isolation, while the SWAP® Valve quickly clears circuits with compressed air.

Digital Data Capture:

The Smartlink® Tracer®VM Interface records flow data directly to the notebook computer, generating .csv files for documentation and analysis.

Networking:

An onboard Ethernet switch allows IP connection, linking the system to a wireless network for easy data transfer.

The Smartflow Mold Validation Cart directly supports operational goals by reducing downtime, improving mold performance, standardizing documentation, and increasing overall throughput.

Cooling efficiency impacts every part of the molding process – and now there’s a faster, more accurate, and more portable way to validate it. With the Smartflow Mold Validation Cart, teams gain a reliable, repeatable tool to benchmark flow rates, diagnose issues, and document cooling performance at any stage of the mold’s lifecycle.

If you’re looking to improve cooling consistency, reduce troubleshooting time, or standardize mold validation across your facility, we’d be glad to help.

Contact your Turner Group Salesperson for more information or email sales@turnergroup.net