September 24, 2025

Sepro’s Next-Gen Control Systems Are Transforming Injection Molding

In the fast-evolving world of plastics manufacturing, automation is no longer a luxury—it’s a necessity. Sepro Group, a global leader in injection molding robotics, is redefining what’s possible with its next-generation control systems. At the heart of this transformation is the Visual 4 platform, a powerful, intuitive, and highly connectable control system designed specifically for the demands of modern molding operations.

Visual 4: A Leap Forward in Control Technology

To be unveiled at the K 2025 trade fair in Düsseldorf, Sepro’s Visual 4 control system marks a significant upgrade from its predecessor, Visual 3. The new system is available in three configurations:

– Visual 4: Ideal for basic pick-and-place applications, controlling up to 5 axes and 24 I/Os.

– Visual 4 Plus: Supports more mold programs and peripheral connectivity.

– Visual 4 Pro: Designed for complex molding cells with multiple robots and extensive automation.

The redesigned operator pendant is 25% lighter, thanks to the relocation of the CPU board to the main control cabinet, enhancing both ergonomics and data security. The capacitive touchscreen, with a modern 10:16 aspect ratio, offers multi-touch gestures and improved responsiveness.

Smart Automation and Seamless Integration

Sepro’s control systems go beyond robot management. They enable full integration of molding machines, robots, and peripheral equipment—from conveyors and sorters to inspection and packaging systems. This centralized control architecture allows molders to manage entire production cells from a single interface, improving traceability, quality, and overall equipment effectiveness (OEE).

The Visual 4 system is also backward compatible, ensuring a smooth transition for existing Sepro users with minimal retraining.

Smart Automation and Seamless Integration

Sepro’s control systems go beyond robot management. They enable full integration of molding machines, robots, and peripheral equipment—from conveyors and sorters to inspection and packaging systems. This centralized control architecture allows molders to manage entire production cells from a single interface, improving traceability, quality, and overall equipment effectiveness (OEE).

The Visual 4 system is also backward compatible, ensuring a smooth transition for existing Sepro users with minimal retraining.

Why It Matters: Control as a Competitive Advantage

Sepro’s philosophy centers on giving molders complete control over their operations. By developing both hardware and software in-house, Sepro ensures seamless integration and customization. This autonomy allows processors to optimize cycle times, reduce waste, and improve product quality – all while adapting quickly to changing production needs.

Whether you’re running a single machine or a multi-robot cell, Sepro’s control systems empower you to take command of your process, your productivity, and your future.

Conclusion

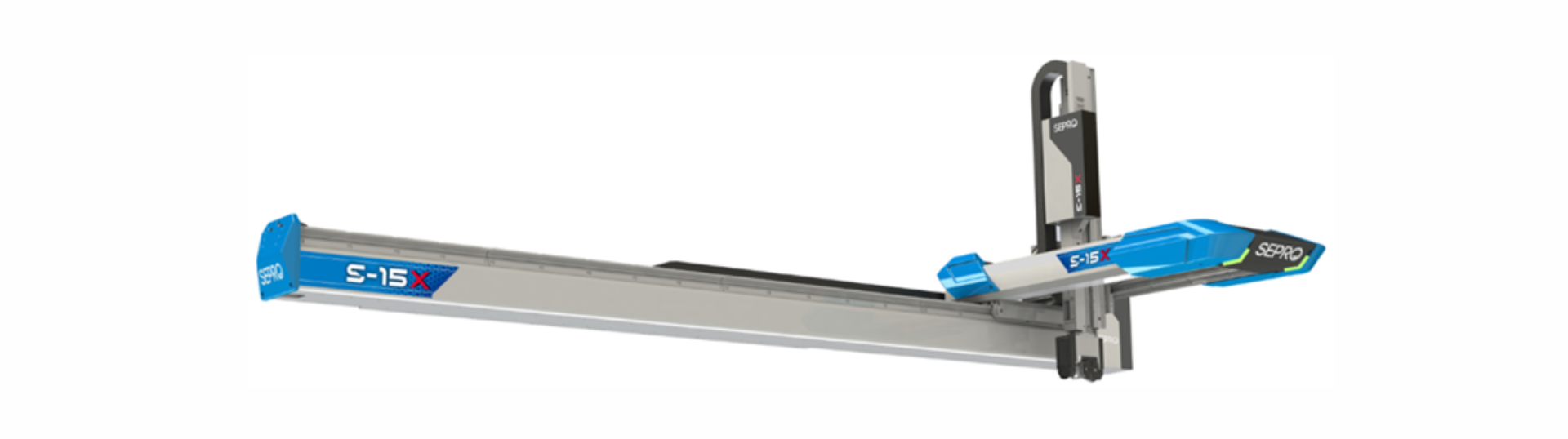

Sepro’s next-gen control systems are more than just technological upgrades—they’re strategic tools for manufacturers looking to thrive in a competitive, automation-driven landscape. With Visual 4 and the S-Line robots, Sepro is not just keeping pace with industry demands—it’s setting the standard.

For more information, contact your Turner Group Salesperson or email at sales@turnergroup.net

Find out more details:

Visit Sepro at K 2025 – Booth: Hall 12 / Stand A36

Links and Sources

Plastics Today | Automation & Sepro’s Next-Gen Robot Control

Plastech | Sepro’s New Visual 4

Modern Business Europe | Meet the Next-Gen S-Line Robots: Faster, Stronger, Smarter