Cycle Time Reduction Tips Without Sacrificing Part Quality

Boosting Output the Smart Way in Plastics Processing

In the plastics processing world, time is money—and cycle time is the currency. Reducing cycle time means more parts per hour, better ROI on equipment, and greater competitiveness. But here’s the catch: cutting time without a plan can lead to warping, flash, poor surface finish, and expensive rework.

So how do you reduce cycle time without sacrificing part quality? It starts with process discipline, smart tooling, and the right technology.

Let’s break it down.

Optimize Cooling Time (Without Risking Warp or Stress)

Cooling is often the longest phase of the injection molding cycle—sometimes 60% or more. Yet many molds are over-cooled “just to be safe.”

- Ensure proper sizing and balanced flow distribution of water-cooling manifolds

- Use thermal imaging or in-mold sensors to identify hot spots.

- Upgrade mold design with conformal cooling, baffles, or turbulent flow paths.

- Improve thermal conductivity using better steel alloys or mold inserts.

Fine-Tune Screw Recovery and Plasticization Settings

Slow screw recovery can quietly eat away at cycle efficiency. Tuning the plasticization phase is low-hanging fruit for many shops.- Back pressure should be just enough to ensure melt homogeneity and consistency, not too much to slow recovery.

- Ensure screw surface speed is optimized for the resin—not causing excessive shear heat.

- Keep barrel zones properly profiled to minimize recovery time without risking unmelted pellets or material degradation.

Don’t Overlook Screw Design

A well-designed screw is more than just a feeder—it’s the engine of your process. Why it matters:- An optimized screw profile tailored to your material and shot size improves melt homogeneity and thermal stability, which can allow faster injection and more consistent pack/hold behavior.

- Custom-designed screws can reduce energy usage and shorten screw recovery time—directly impacting cycle time.

- For filled or heat-sensitive materials, screw geometry is critical for minimizing degradation or clogging.

Use Scientific Molding methods to dial in the process

Scientific molding gives you the tools to run faster with control.- Cavity pressure sensors to determine exact gate freeze time—then set hold time accordingly. No guesswork.

- Set injection speeds to maximize fill rate without introducing shear, burn marks, or jetting.

- Clamp force should be just enough plus a safety margin to seal the mold. Over-tonnage stresses and wears the tool, and slows the cycle.

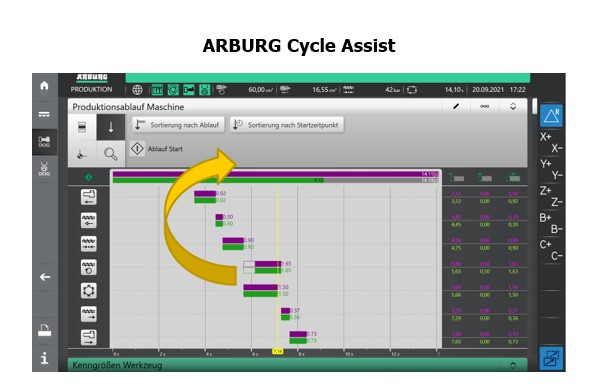

Smart software like ARBURG’s Cycle Time Assist acts like a second set of eyes on your machine.

ARBURG’s Cycle Time Assist gives real-time feedback on cycle segmentation. It helps identify:- Idle phases between steps

- Opportunities to parallelize movements

- Clamping, ejector, and handling delays that are easy to miss

Upgrade Your Mold Design

Tooling design plays a massive role in cycle time and consistency.- Hot runners and valve gates reduce runner regrind and cycle time.

- Use high-efficiency ejection systems to reduce mold open/close delays.

- Consider robotic part removal or end-of-arm tooling for consistent, fast demolding.

Automate Where It Makes Sense

Even small-scale automation can help trim seconds and boost consistency.- Robots and Sprue pickers reduce mold open time.

- Vision systems detect defects in real-time, allowing faster QC and less rework.

- Customized end-of-arm tooling can reduce handling time and enable lights-out production.

Measure Everything, Change One Thing at a Time

Use cycle monitoring software, data logging, and high-speed cameras to analyze each segment of the cycle. Often, the biggest wins are in the transitions—not the molding itself.

And remember: change only one variable at a time to maintain traceability and control.

In Summary: Don’t Just Go Faster—Go Smarter

Cycle time reduction is about strategic efficiency, not shortcuts. With optimized screw design, scientific molding, smart software like ARBURG’s Cycle Time Assist, and well-planned automation, you can boost throughput without compromising your process or part quality.