August 6, 2025

Cool Under Pressure: Monitoring and Regulating Mold Cooling in Plastics Processing

In plastics processing, few things affect cycle time, part quality, and scrap rate as much as cooling—yet it’s often treated as a “set it and forget it” utility.

But times are changing. As processors chase tighter tolerances, faster cycles, and fewer rejects, mold cooling is getting a much-needed upgrade in visibility and control. Today, smart monitoring and precise regulation of water flow and temperature are becoming key levers for optimizing performance—and gaining a competitive edge.

Here’s why it matters, and what processors are doing about it.

The Real Cost of Inconsistent Cooling

In injection molding, cooling can account for 60-70% of the total cycle time. If your water isn’t flowing evenly or at the right temperature, you’re likely facing:- Warped or dimensionally unstable parts

- Uneven surface finishes

- Extended cycle times

- Higher scrap and rework rates

Even worse, cooling issues often go undetected until quality complaints—or production stoppages—start piling up.

What Processors Are Doing Differently Today

Modern plants are no longer guessing when it comes to water management. They’re adopting smart cooling systems that measure, monitor, and adjust flow and temperature in real time. These tools give visibility into:- Flow rate per circuit

- Inlet and outlet temperature deltas

- Pressure fluctuations

- Alarmed anomalies (e.g., blocked circuits or scaling)

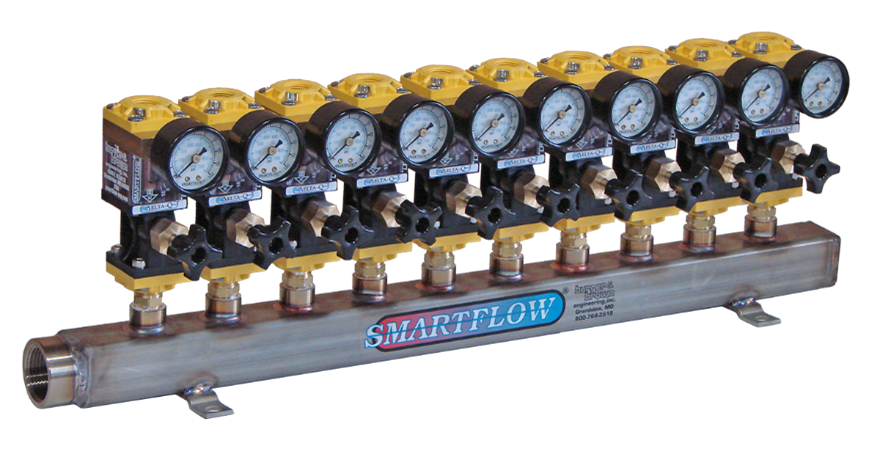

Systems like Smartflow®’s flow monitoring and data logging solutions provide operators with clear dashboards and digital records, making it easy to identify and address cooling issues before they affect part quality.

Legacy Switching Tracer® Flow Meters – SmartFlow USA

From Monitoring to Regulation

Monitoring is step one. The next level? Active regulation. With closed-loop controls, processors can automatically:- Adjust flow to maintain consistent cooling

- Regulate temperature based on part geometry or resin sensitivity

- Balance flow across complex tools with multiple zones

This is especially useful in multi-cavity molds, where flow imbalance can lead to inconsistent parts and uneven wear across cavities.

Integrating Cooling with the Process

More advanced plants are linking their cooling systems directly to the machine controller or MES platform, enabling recipe-based flow and temperature settings for every mold. This ensures that every setup—whether it runs in Shift A or Shift C—meets the same process requirements. Add predictive analytics or cloud-based monitoring, and cooling becomes a controllable process variable, not a mystery.The Payoff: Better Parts, Shorter Cycles, Lower Scrap

Tight control over cooling translates directly to:- Reduced cycle times without compromising quality

- Fewer warps, sinks, and dimensional rejects

- Consistency from shot to shot—and shift to shift

- Lower maintenance costs from reduced scaling and corrosion

For companies operating in automotive, medical, or tight-tolerance consumer goods, that kind of repeatability isn’t a luxury—it’s a necessity.