Blog

Turner Talks

Stay updated on products, industry news and company information.

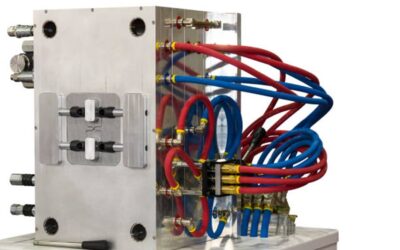

Heat Transfer in Injection Molding Performance

Heat transfer doesn’t get the spotlight in injection molding but quietly drives cycle time, part quality, and process stability every day.

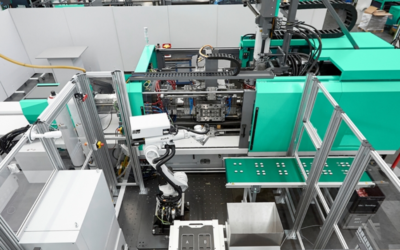

Premium Use of Space in Plastics Processing

Smart space use in plastics manufacturing drives efficiency. Explore compact layouts, automation, and modular design for better performance.

ARBURG Technology Days 2026 – From Concept to Manufacturing: OEMs

Technology Days brings together decision makers from across the plastics value chain. See how technology turns into scalable production.

ARBURG Technology Days 2026 – Mold Technology

Discover how moldmakers transform advanced systems into consistent, repeatable production – driving the future of plastics manufacturing.

MD&M West 2026

Join Us at MD&M West 2025: Experience the Future of Medical Design and Manufacturing Innovation! Will we see you there?

ARBURG Technology Days 2026

Discover why thousands of plastics industry professionals attend ARBURG Technology Days in Lossburg, Germany. Event on manufacturing systems.

2026: Challenges and Opportunities for Plastics Processors

How manufacturers can navigate economic uncertainty, workforce challenges, automation, and supply chain shifts to unlock new opportunities.

Wishing You a Happy New Year from the Turner Group Team

The Turner Group extends its warmest wishes for a Happy New Year to our valued customers, partners, and colleagues.

Season’s Greetings from the Turner Group Team

From all of us at Turner Group Inc., we wish you a joyful and peaceful holiday season. May this time of year bring you moments of joy.

The Training Paradox in Plastics Manufacturing

Discover why undertraining costs the plastics industry—and how AI and structured supervisor training boost performance, retention, and ROI.

Innovating Cooling Diagnostics: Smartflow Mold Validation Cart

In injection molding, cooling efficiency is one of the most underestimated drivers of cycle time, part quality, and mold longevity.

Vertical Clamp Injection Molding

From Gravity-Assisted Loading to Automation-Ready Cells: Vertical Molding Sets the Standard for Insert Molding

Ready to Talk?

We will respond as soon as possible.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.